CE Approved Rotary Knob Control Pulse TIG 250p AC DC Welding Machine with IGBT Module

Package Size 54.00cm * 33.50cm * 60.00cm Package Gross Weight 22.000kg Guangzhou Jskwed welding equipment Co., Ltd is lo

Description

Basic Info.

| Model NO. | tig250p acdc-1 |

| Electric Current | Pulse |

| Work Form | One-Body |

| Type | TIG Welder |

| Rated Output Current | 250A |

| Rated Output Voltage | 20V |

| Input Voltage | 220V, 1 Phase, 50-60Hz |

| Machine Weight | 17.7kg |

| Transport Package | Export Carton |

| Specification | 475*245*420mm(machine size) |

| Trademark | JSKWED |

| Origin | Guangzhou |

| HS Code | 8515390000 |

| Production Capacity | 3000 Sets Per Month |

Packaging & Delivery

Package Size 54.00cm * 33.50cm * 60.00cm Package Gross Weight 22.000kgProduct Description

Guangzhou Jskwed welding equipment Co., Ltd is located in the beautiful charming city - guangzhou. The company has a number of professional team engaged in the research and development, management, sales and service of inverter welding machine(tig welding machine/mig welding machine/plasma cutting welding machine) for many years, advanced SMT technology, assembly equipment, perfect product testing means and quality assurance system form a complete set of control process, to ensure the product consistency, reliability.Welding machine China manufacturer

tig welding machine/mig welding machine/plsama cutting welding machine/inverter welding machine/welding equipment/welder/tig acdc welding machine/tig dc welding machine/tig acdc welding/tig dc welding/tig 3 in welding machine/welding/welding machine factory/welding machine manufacturer/welding machine fabrication/welding fatory/welding trading/welding manufacturer/igbt/single tube/inverter welding machine

TIG-AC/DC/MMA 250A PULSE INVERTER WELDING MACHINE

| Model No. | tig-ac/dc 250p | Pulse Current | 10-250A | Clean Width | 25%-75% |

| Input Voltage | 1 phase AC220V50-60Hz | Welding Current | 10-250A | AC Frequency | 50-150Hz |

| Rated Output Current | 250A | Pulse Frequency | 0.5-100Hz | Degrees of enclosure protection | 1P21S |

| Rated Output Voltage | 20V | Pulse Width Ratio | 0.2-0.8 | Dimensions | 475*245*420mm |

| Rated Iutput Power | 7kw | Down-Slope Time | 0.1-5s | Package size | 540*335*600mm |

| No-load Voltage | 56V | Crater Arc Current | 10-250A | machine Weight | 17.7kg |

| Current Adjusting Range | 10-250A | Post Flow Time | 5-25s | Weldable thickness of aluminum sheet | 0.8-5mm |

| Start Arc Current | 10-250A | utilization factor | 60 | IGBT | module |

| Up-Slope Time | 0.1-5s | Efficiency | 83% |

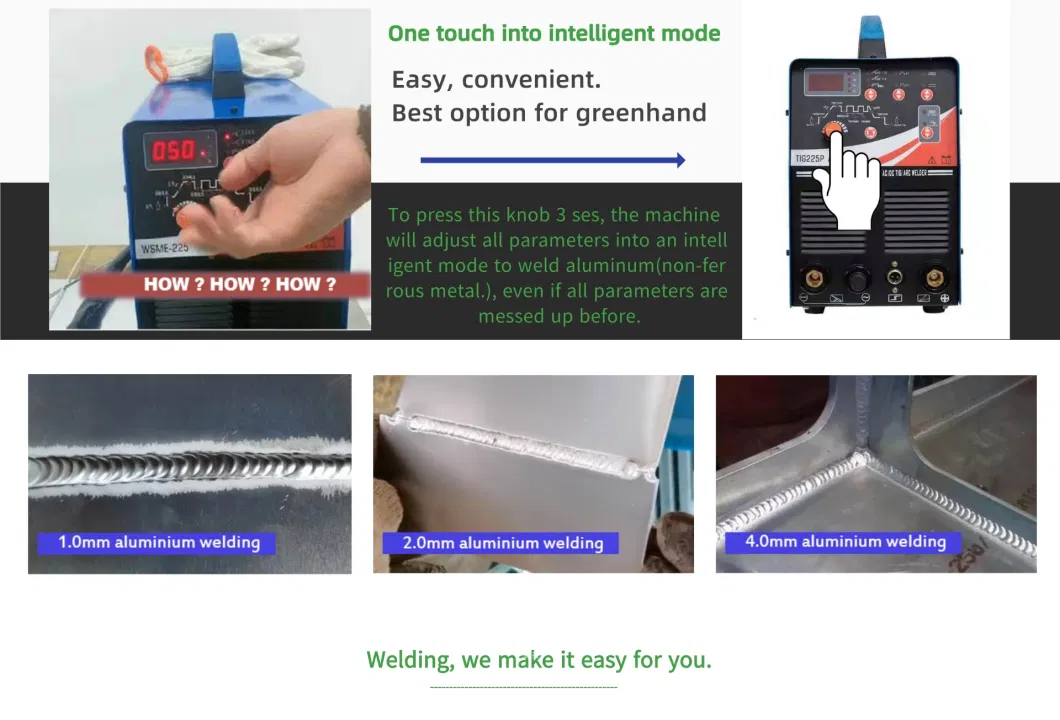

Rotary knob panel, 220v,1 phaseeasy switchover, which can meet different demands.Input voltage customized, dual voltage optional.Multifunctional(AC/DC/MMA). Good at welding aluminum and stainless steel.Two kinds of control panel. Digital and rotary knob, every parameter can be adjusted accurately.All machines could work with pedal.High frequency arcing, high performance, excellent effect in thin or thick sheet.

CHARACTER:

AC frequency adjustable, pulse and non-pulse, very good machine to weld nonferrous metal.We use DC function to weld stainless steel, and DC low-frequency welding. MMA function can work well with welding rod,excellent effect to weld low-carbon steel, high-tensile steel and Cr-Mo steel.We use stable module, and every components of us are high-quality and completely new.Every machine equipped with torch, ground electrode, power line and air pipe.Colors and styles could be customized, the current colors are red, blue, black, orange.

WHY CHOOSE US:

We've been engaged in the researching and manufacturing of TIG AC/DC and TIG DC machine over 10 years! We put the most of resources in this type of machine and its accessories because our purpose is producing the best TIG AC/DC welding machine in the industry.

Strict Quality Control:1.Our quality starts from the elemets. All parts are full new, refusing the used one. Our machine mainboard is made by ourself all the parts was in strictly controling.2.Our quality controling systems are stopping the defect before packing; So we arrange at least 5 QC stations, In an assembling line ; then every tiny part in the charge of one worker ,even every screws should be marked.3.The scientific production management 6S , prevent the mistakes by human being at the upper limits.4. Our products are strictly tested 100% before delivery. And our products are able to meet or exceed some of the industry's most rigid standards. We can ensure you will be satisfied with both performance and durability.

Prev: TIG 200 Acdc Pulse Welding Machine Spot Welding Functions

Next: Orbital Pipe Tube Welding Tractor for Tank Construction Machinery with MIG Welder Power Source

Our Contact

Send now